Auto Dispatching: Save Time, Cut Costs, and Improve Deliveries

Over the last decade, the logistics automation market has grown tremendously. The sector attained a value of $49.7 billion in 2020 globally, and...

MODEX razzle-dazzle was in full force as supply chain vendors poured into the Georgia World Congress Center's 1.5M square feet last week. It was electrifying, and everyone was thrilled to be there.

Our team had an absolute blast at our booth. SO MANY people stopped by to shoot hoops and talk. And we were particularly excited to talk about our latest TMS feature releases: SmartPOOL Distribution, Freight RateHACKER, and SmartTRACK.

The underlying theme at MODEX, no matter what session or booth you visited, revolved around labor issues. Attendees were looking to solve labor problems. And vendors were presenting automation and software in ways tied to solving that problem.

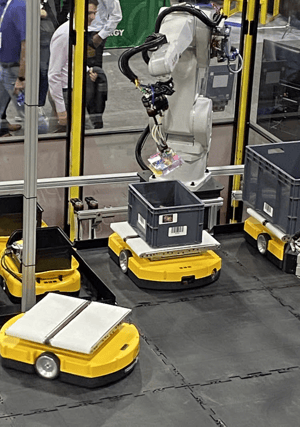

With nearly 200 robots on display across the convention center, you almost lost the sense that this wasn't a tech convention. Plus One Robotics Founder, Erik Nieves, mentioned in one of his sessions that last year was the first time that non-auto robotics growth was larger than auto in North America. And just where are all the robots going? He said the bulk of these are hitting DCs, sort hubs, and fulfillment centers.

One presenter explained how to determine if now is the time for you to invest in autonomous mobile robots (AMRs), saying the number one business case is travel. If you have workers traveling all over the warehouse, investment is a good idea. Additionally, if your workers are picking to orders currently, then moving to a sortation process that uses AMRs makes sense.

If you have heavy forklift use, one presenter pointed out that pallet-based workforce AMRs are a good investment and are safer than forklifts as they typically have sensors with a 360° view. It was noted that this safer option could reduce forklift incidents, which statistically happen at least once a year at a warehouse, costing an average of half a million dollars.

One MODEX session covered how to use AI onboard AMRs to cut down on safety violations. It was explained that by using AMR tech roaming around your warehouse, you could capture incredible amounts of data and identify patterns, allowing you to map risk areas and reduce ops breaches per hour.

There were all kinds of fully automated, to people-robot workflow combinations on display. And the tie-in to how it can help businesses with current labor shortages was strong.

Another repetitive message at MODEX was the importance of getting Ops buy-in when rolling out automations and warehouse robotics. Story after story was shared about how much money and time is wasted by not involving warehouse operations in the decisions and rollout of robotics.

In fact, if you're investing significantly in a robotics program, one presenter suggested you should create a production engineering department to oversee implementation and management. Why? Because your Ops folks are not likely to invest as much time figuring out how to work with your robotics. And your maintenance department will only ever truly be in break-fix mode. But a production engineering department can focus on ensuring the maximum value out of your robotics investment.

So you've decided on a robotics program - now what? It was advised that you better plan for leeway time as system integrators (the guys and gals who integrate your ERP/WMS to robots) are absolutely hot setting up warehouses all across America right now. Their lead times are extremely extended, so you'll want to factor this in during planning. However, the good news is that there are more and more system integrators up to speed on material handling, and not just warehouse experience, than ever before.

Lastly, a fact of life that we've all come to know: this may be our new normal. Our supply chain is still kinked since COVID. And many consumer behaviors have become sticky that businesses are having to accommodate. There is no horizon on these realities, with labor challenges a part of that equation.

The experts at MODEX were unanimous in asserting the need to invest in robotics and automations to meet customer demand and stay competitive. ...we suspect there will be a lot more robots on display at the next MODEX.

Check out our 3 ebook bundle, The Ultimate Supply Chain Visibility Guide!

This bundle gives you:

Download the bundle to access tips on creating agile supply chains!

Over the last decade, the logistics automation market has grown tremendously. The sector attained a value of $49.7 billion in 2020 globally, and...

MHI's ProMat 2023 in review: The premier material handling and logistics conference concluded last week. Our team connected with many retailers,...

Last-mile logistics remains a considerable challenge for shippers, and now dynamic carrier pricing, autonomous vehicles, and drones are bringing...