The First Shipping Mile - How to Optimize Inbound Shipping

Inbound shipping costs are often overlooked when businesses investigate supply chain savings, however, industry estimates put inbound shipping at...

How confident are you right now about your ability to forecast demand accurately? With ongoing supply chain disruptions, ensuring adequate lead times is very challenging. Here are 5 tips to help.

One of the first steps to improving your inventory forecasting is to classify your inventory to focus your attention on:

For fast-moving items, you need a good handle on supply and demand. You also want to ensure you keep enough inventory on hand for the items that generate the most profit. For slow-moving items, you need to make sure you’re not overbuying. Stockouts create lost sales opportunities, but not all stockouts are created equal. You want to assess the impact of any potential stockouts in terms of the effect on your total revenue.

One way to improve your forecasting is to focus on the items with the most demand that generate the greatest profit.

For years, even high-volume shippers relied on spreadsheets to track sales. Taking into account historical and seasonal sales patterns, they managed inventory effectively. Today, consumer behavior changes quickly, and the lead time for goods is often long.

Companies need more sophisticated computer models that integrate historical data, seasonal trends, supply chain issues, and consumer behavior to produce more accurate forecasts. You also want algorithms that can forecast demand based on promotions. What happens to your inventory if you discount?

You also need to monitor the accuracy of your forecasting models. By tracking over time, you can evaluate performance. If your computer-generation forecasts are off track, you know that you need to make manual adjustments before reordering or adjusting model parameters.

If forecasts match up with performance, you can automate much of the reordering process by allowing your inventory management system (IMS) to handle purchase orders and replenishment through automation.

Many shippers found inventory problems when supply chains started getting backed up. Make sure your forecasting models pull in all your shipping data and trends. If you know it will take longer to fill the shelves, your models must account for shipping delays to maintain current inventory levels.

You may also want to review your safety stock levels. Often these are set and only reviewed annually, but increasing lead times will require higher safety stock levels.

Any forecast is only as good as the underlying data. Make sure you are using real-time data across all of your sales channels. In today’s multichannel sales environment, it can be easy for data to be out of sync. If your inventory counts are off, your forecast will be too.

You may also want to increase your cycle counts, especially for hot ticket items. One recent study examined inventory at seven grocery, general merchandise, and retailers across nearly 100 stories. They found that inventory counts for 60% of the SKUs they analyzed were inaccurate.

Some high-volume shippers only do monthly forecasts or look at inventory levels when they get system alerts that stock is running low. This makes it easy to miss emerging trends. You can adjust forecasts more quickly by doing weekly checks on your high-priority items and comparing them to projections.

Not only will you catch changing demand more quickly, but you will also more readily see when there is routine demand for products. Recurring demand can be when sales are consistently increasing, decreasing, or subject to seasonal trends. Forecasting is easier when you find products that follow consistent, logical patterns. You can then automate reordering and inventory levels and focus on items that do not fit the pattern.

Better inventory forecasting helps everything run more smoothly. It results in fewer stockouts, dead stock, or costly oversupply. Forecasting also helps you manage your freight and shipping costs as well. For example, improved forecasts let you reduce rush charges and optimize shipments.

For more information on improving your supply chain logistics and reducing your shipping costs, contact the experts at FreightPOP - we'd love to help!

Inbound shipping costs are often overlooked when businesses investigate supply chain savings, however, industry estimates put inbound shipping at...

Seemingly impossible not to notice, facility and distribution centers are going up at an incredible rate across America as retailers and D2Cs invest...

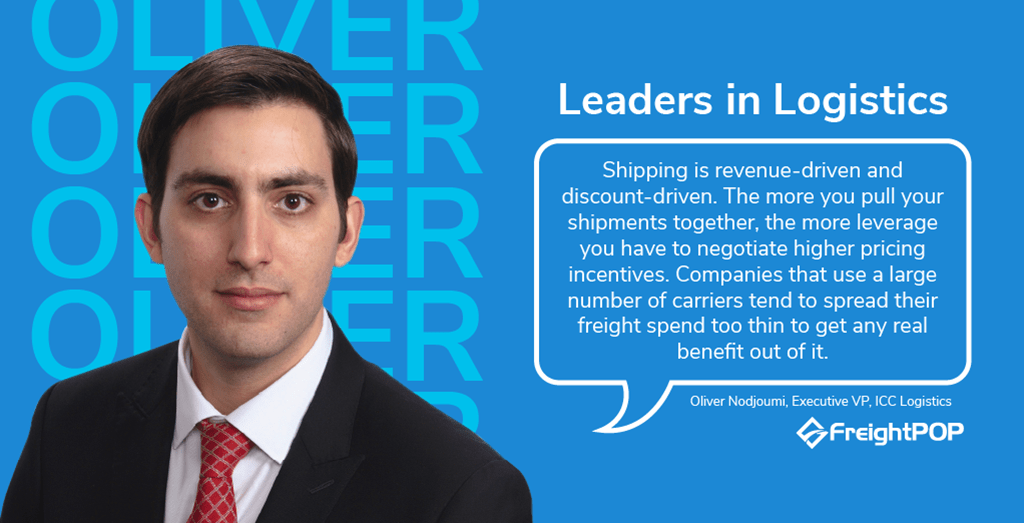

ICC Logistics' Oliver Nodjoumi talks about the importance of shipping data, how to revamp shipping service allocation to save money, and forecasts on...